I want to replace a stepping motor with a servo motor, but the servo motor does not fit my budget.

Is there any solution to achieve servo motor performance at a reasonable pricing?

CM3 uses a stepper motor and adapts Muscle's proprietary control technology to achieve performance comparable to a servo motor at a lower cost.

Performance improvement by no step-out

1 No mis-positioning.

Since CM3 has the same closed-loop control as servo motors, there is no step-out that would cause mis-positioning.

Encoder resolution:12,000ppr

2 By maximizing the torque of the motor, the size of the machine can be reduced.

Since there is no step-out, larger size of motor will not be required for safety margin. CM3+ produces powerful torque from a smaller body.

3 Rapid acceleration / deceleration is possible

Stepper motors are not suitable for high acceleration and deceleration due to the risk of step-out. However, CM3 does not have step-out, so it can be used in semiconductor-related equipment where fast tact time is required.

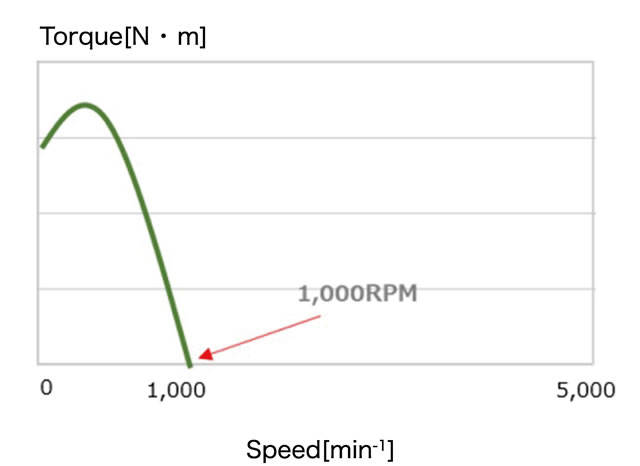

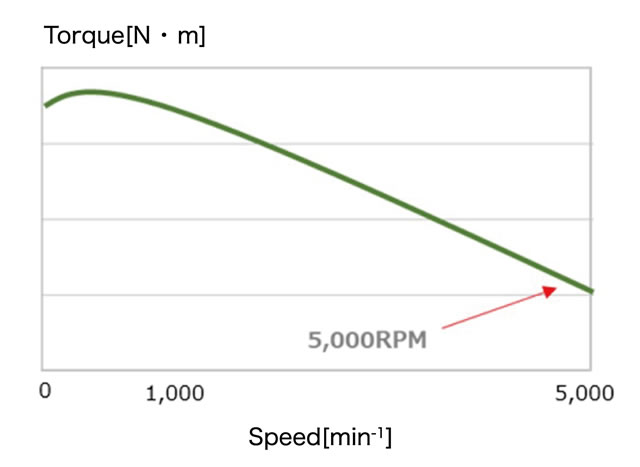

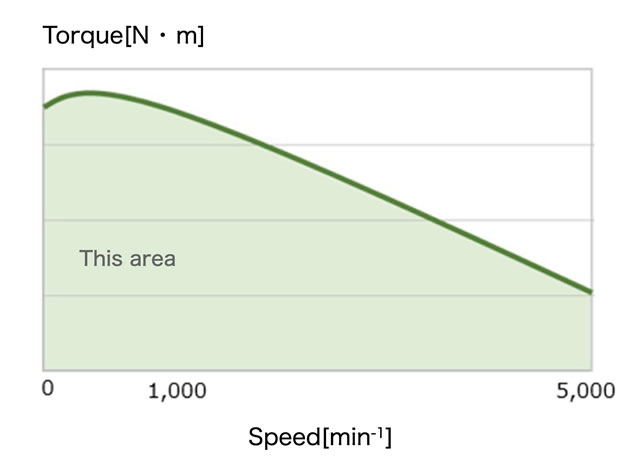

Maximum speed

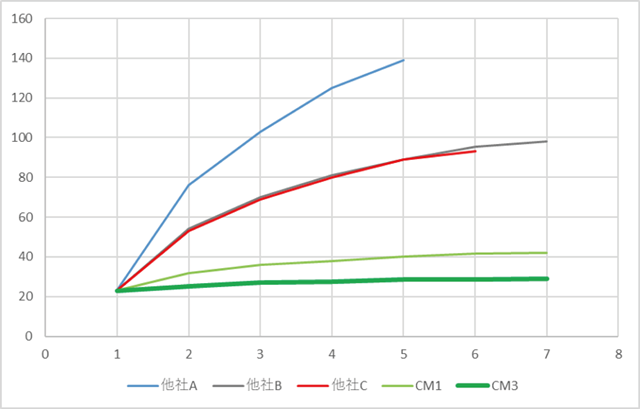

Stepping motor

Stepper motors can output high torque at low speeds, but their maximum speed is not very high.

CM3

CM3 has a maximum speed of 5000RPM, which is the same level of speed as a servo motor.

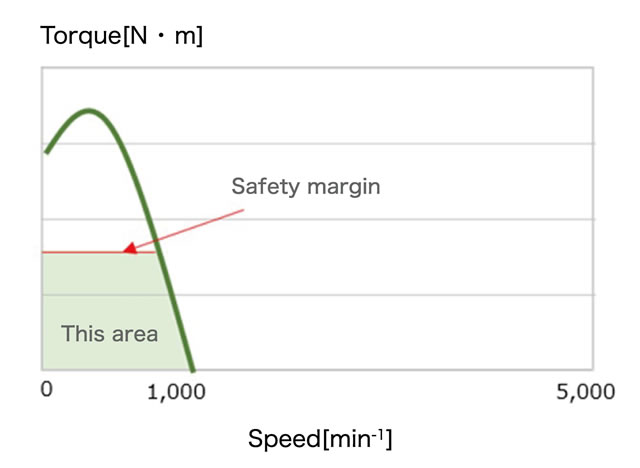

Torque range

Stepper motor

Stepper motors have a risk of step-out, so the safety margin must be considered.

CM3

CM3 can produce more torque than a servo motor at low speeds.

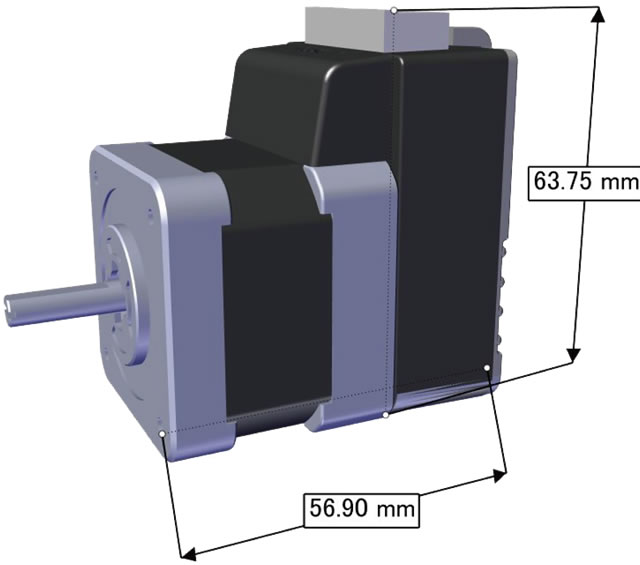

- I am using a Nema17 (42mm) stepper motor with a length of 47mm,can I replace it with a CM3 to reduce the motor size?

- That motor has a maximum torque of 0.49Nm in the specifications, but considering the safety margin, the usable torque is about 0.25Nm.

For CM3-17S, Nema17 (42mm), length 36mm, the maximum torque is 0.32Nm.

By the CM3's integration, the total dimensions are a little larger, but by reducing the size of the motor, the total weight can be reduced from 370g to 290g.

Low vibration and noise reduction

Since a stepper motor stops at each step, the vibration becomes large.

CM3 have smooth motion with minimal vibration by vector control.

Energy saving and low heat generation

When a stepper motor is operated continuously, the temperature of the motor keeps rising.

Therefore, it is necessary to adjust the operating time and the stopping time of a general stepper motor to suppress the heat generation of motor.

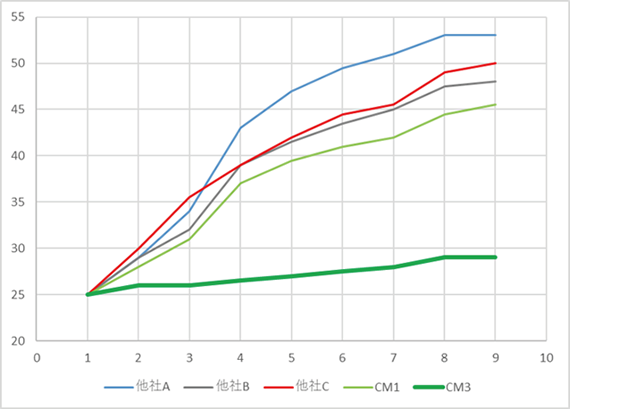

Temperature comparison when motor is stopped (no load)

Compared to a general stepper motor in which a constant current always flows, CM3 requires almost no torque to hold the position when the motor is stopped without an external load, so only the minimum current should flow and heat generation should be suppressed.

100RPM temperature comparison during continuous rotation (no load)

In general stepper motors, the motor temperature keeps rising due to continuous operation, and it stops due to the temperature protection function of the driver, but CM3 can suppress heat generation by optimal current control. It can also be used for long-term continuous operation.

- How much is the selling price?

- Please contact our distributor listed in the URL below for the selling price.

Distributor List