Challenge to low-cost innovation

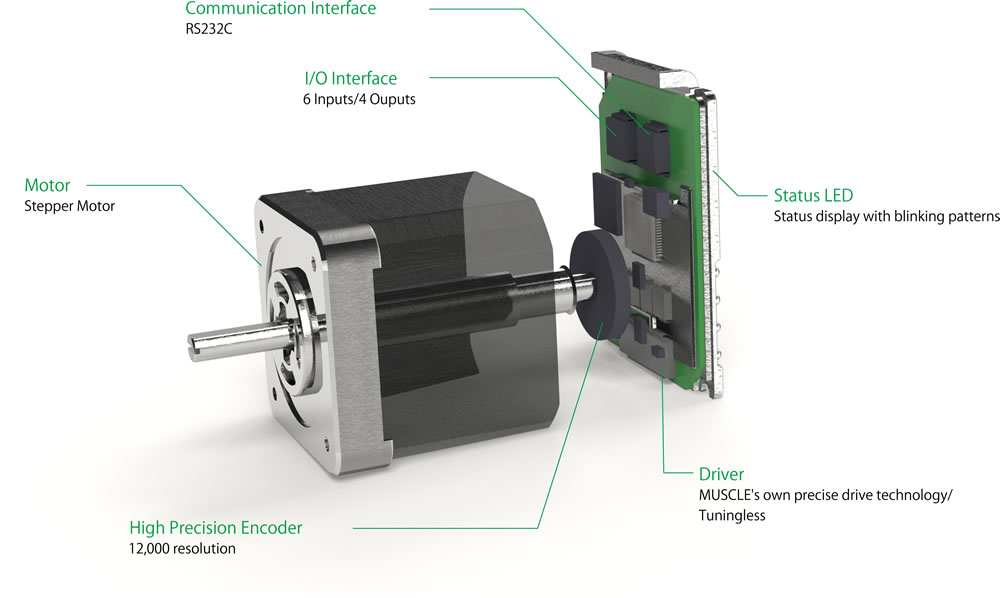

Integrated AC Servo System

COOL MUSCLE 3 is the Integrated Servo System equipped with devices that are required for motor control such as a driver and encoder. By eliminating complex functions and reducing them to the essentials, COOL MUSCLE 3 can offer a simpler and more affordable solution.

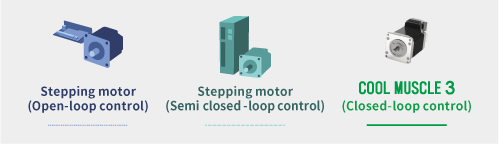

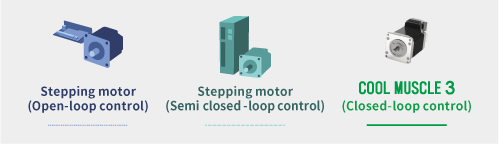

Achieve servo equivalent performance using a stepper motor

COOL MUSCLE 3 eliminates stepper motor’s particular weak points such as step-out, heat generation, high acceleration / deceleration, noise and so by Muscle's original control technology, and realizes performance comparable to servo motor. High-precision motion control can be achieved at low cost with a simple configuration.

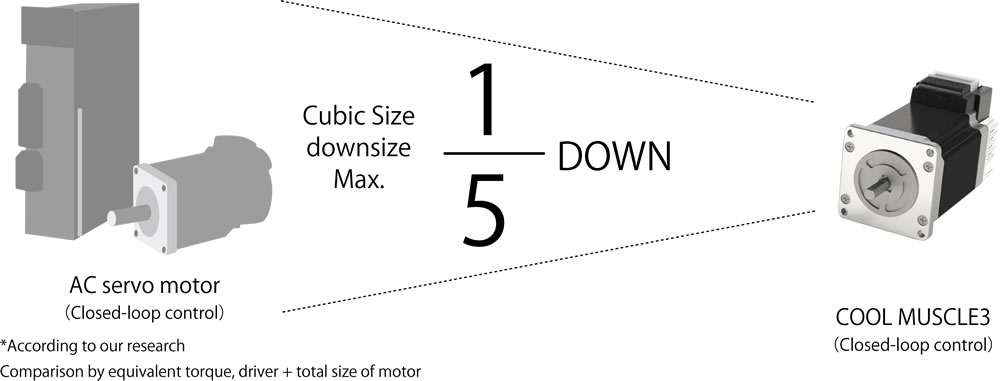

Contributes to space and wiring saving

Built-in driver, controller, and encoder in the back of a motor. Wirings and the total volume can be significantly reduced.

Especially recommended for desktop devices, mobile devices, and small size equipment where it is difficult to secure control panel space.

3 control types

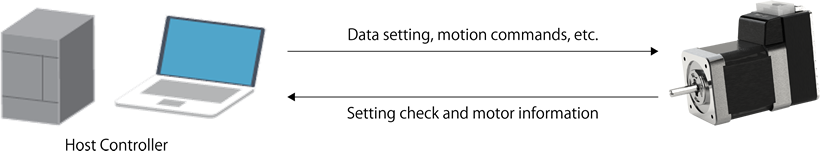

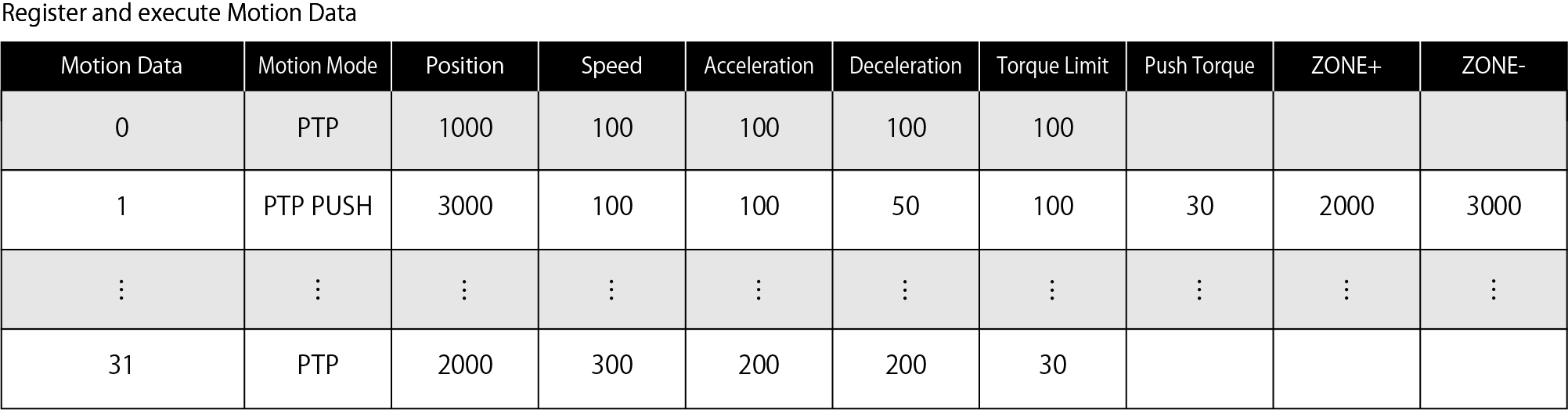

Direct Type (Communication Control Type)

You can operate the motor directly by sending and receiving commands via RS232C serial communication.

Positioning to any position is possible by simple settings such as position, speed, and acceleration.

Up to 32 points of Motion Data can be stored and executed.

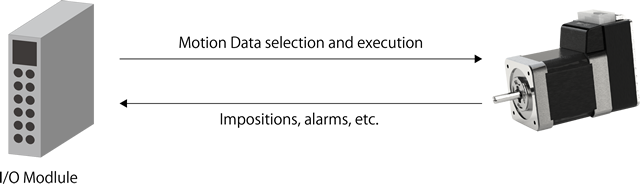

I/O Type

Up to 8 points of Motion Data can be saved in CM3.

Motion Data can be selected and executed by signals from I/O port on PLC.

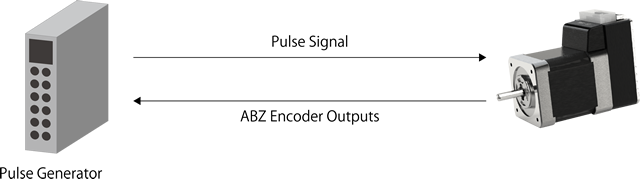

Pulse Type

Control CM3 by pulse signal from PLC.

CM3 has an ABZ output function so it can be replaced without changing an existing system.

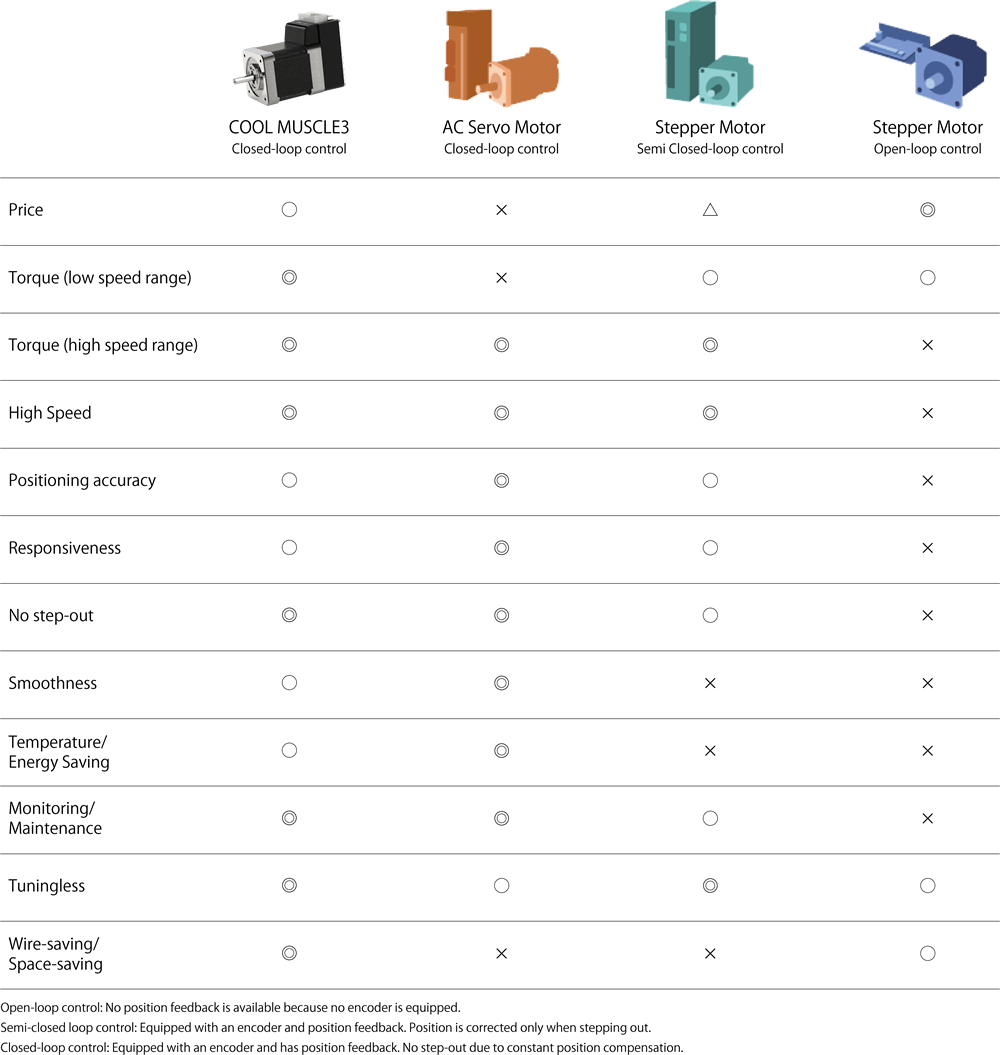

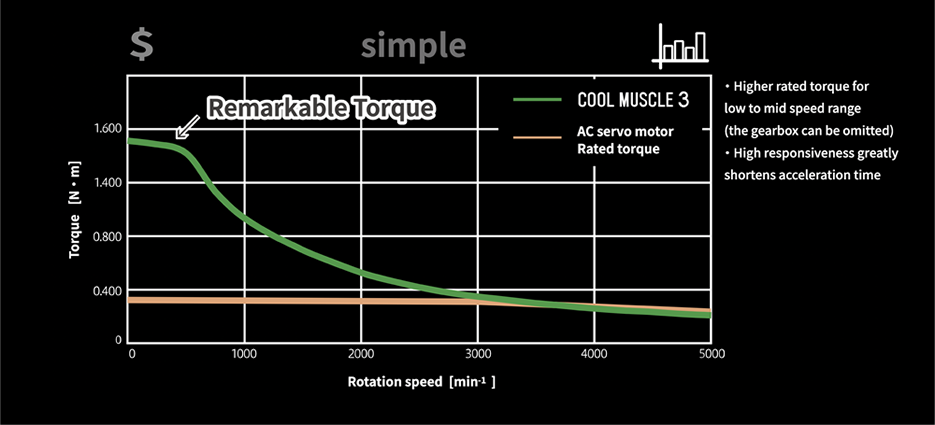

Higher performance than servo motor

Servo motor must be used within the rated torque (torque of about 30% of the maximum torque) when operating servo motor continuously. Since COOL MUSCLE 3 can keep producing the maximum torque even during continuous operation, it is possible to output a large torque from a small size motor at a lower speed range.

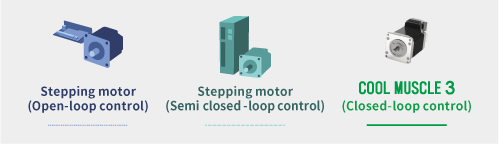

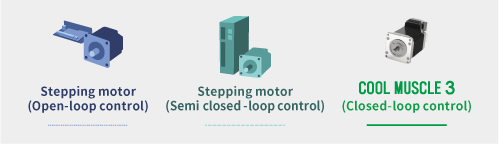

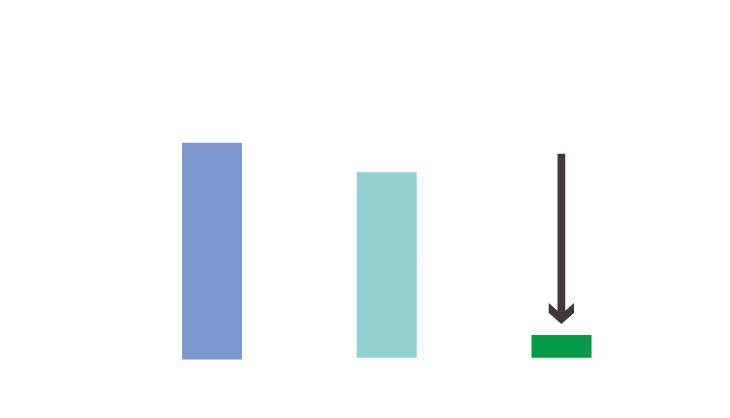

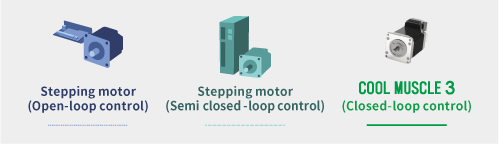

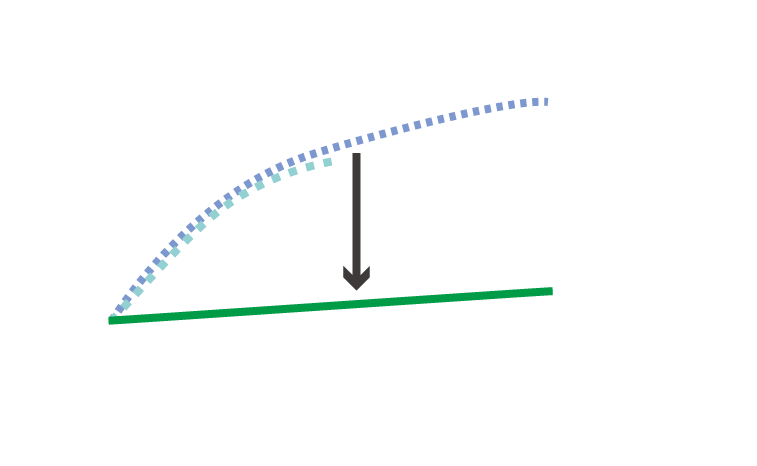

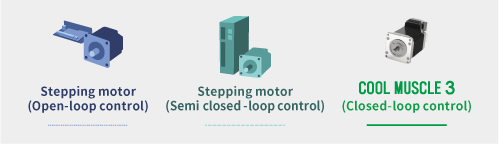

Stepper Motors Comparison

- Torque (low speed range)

- Maximum Speed

- Speed Stability

- Responsiveness

- Loudness

- Current Level

- Temperature

High torque output is possible even at low speeds without risk of step-out

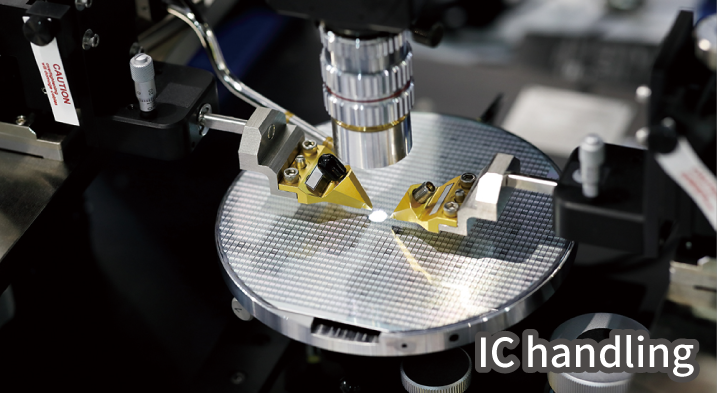

■Application Example

Reduced Motor Size ・ Utilization when Work-Weight increases

Suitable for products that require powerful and precise motion in limited space.

High-speed control equivalent to servo motor

■Application Example

Moves Quickly and Stops Quickly

Ideal for products that require quick and accurate positioning.

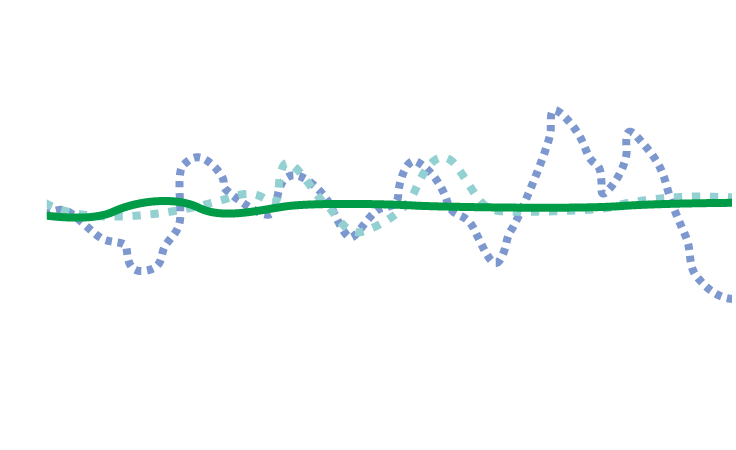

Speed ripple is small at continuous speed.

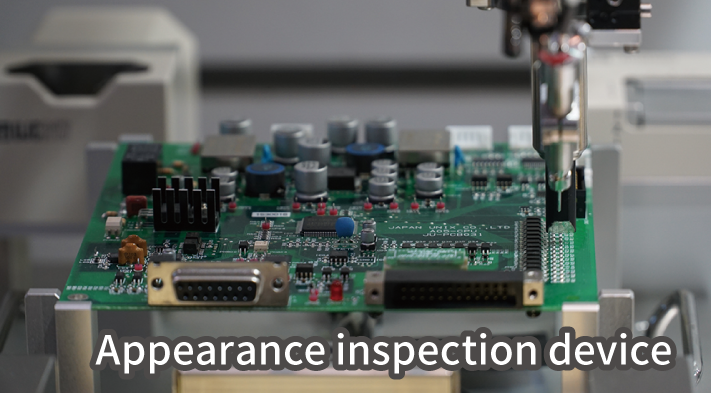

■Application Example

Improvement of measurement accuracy

Suitable for equipment that require to rotate precisely at a constant speed against command speed.

High acceleration and deceleration control reduces repetitive operation time greatly

■Application Example

Improvement of throughput

Suitable for products that require higher throughput by where short time & short distance positioning are necessary.

Smooth motion by vector control makes it quieter

■Application Example

Great Quietness・Low Vibration

Suitable for equipment that requires quietness and image inspection equipment that dislikes vibration

The current is controlled according to the load situation. It keeps current consumption at minimum level.

■Application Example

Energy Saving

Suitable for AGVs, etc. which are battery-powered and require energy savings.

Low heat generation allows long-term continuous use

■Application Example

Continuous operation

Suitable for products with high speed continuous operation with a duty ratio of over 50%.